UC 3.1 Use Life Estimation

The continuous development of this use case is a collaborative effort between Signify, TU Delft, and Mek Europe, three vital partners of the project. Together, their concerted endeavors exemplify a commitment to innovation and progress, as they work towards refining the project’s functionalities and applications.

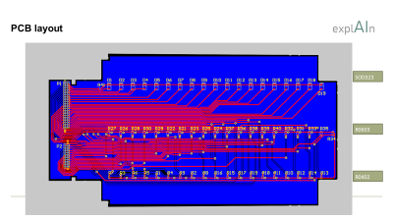

To guarantee high quality products, electronics manufacturing contains many inspection steps like after PCB assembly (using machines from MEK) or after the final assembly of the product.

The relationship between the lifetime of electronics and the visual inspection data obtained during production is unknown and cannot be found using these existing methods.

Impact: Applying AI and ML, specifically deep learning, can give new insights into process optimization, reveal design changes to improve product lifetime, and increase the performance of defect detection to minimize false calls and slip of non-conforming products.

Current Status: First PCB design is created, with critical components placed. Visual inspection will be performed by MEK. Accelerated tests are started and first results are available. TUD PhD student will work on the generation of AI models to connect process variations with lifetime performance

User Interface

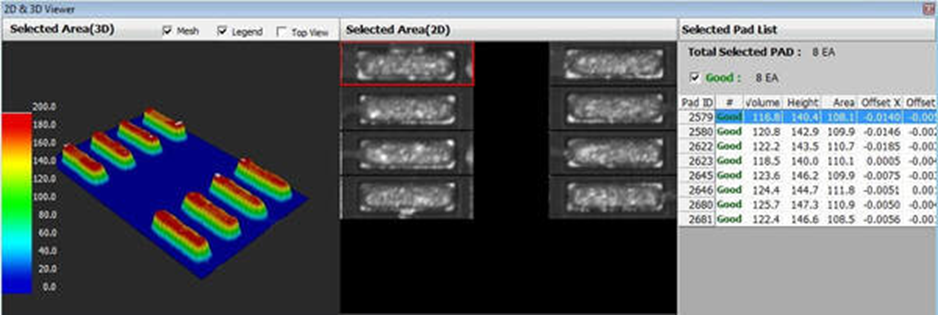

A first version of a UI has been developed with TU DELFT, which allows operators to detect anomalies and explore their root causes explains the anomalies.

This can be related to e.g., an insufficient amount of solder or a misplaced component.

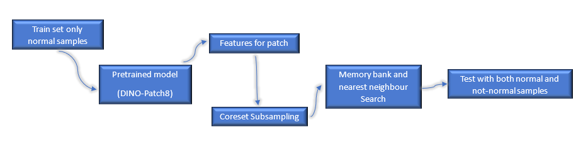

ML Model Summary

Different lighting images from the MEK machine gives the diversity for the user and enables to model to have understanding on the possible defects. We have been exploiting CAM-based techniques to produce heatmaps and masks.

Explainer Component Overview

Further assessment collects the feedback on associated labelling and scoring for fine tuning the threshold for classification task. This will help to have good understanding if the predicted value for the anomaly score make sense or not. A mock-up will be built that:

- Indicates the level of anomaly.

- Explains the reason for the anomaly (e.g., tilted; insufficient amount of solder, etc.).

- Based on the anomaly places the actual component into a lifetime bucket

This work is currently in progress.